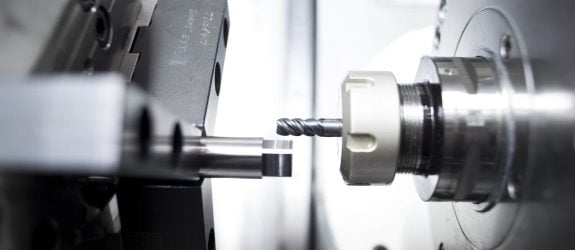

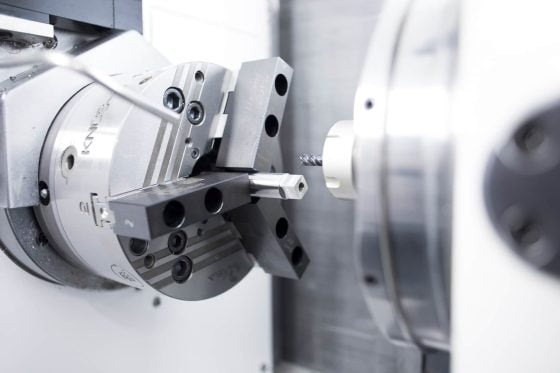

At FT Gearing Systems, we offer comprehensive CNC turning services, using the latest technologies and techniques to produce precision machined parts for a wide range of demanding industries. We have strong partnerships with machine tool manufacturers Mazak and Citizen, enabling us to deliver exceptional quality and accuracy in every project we undertake.

One of our key capabilities is the production of super-precision geometric tolerances, demanded for in-house machined gear blanks and bearings. Using advanced processes and equipment, we are able to achieve the tightest tolerances and highest levels of accuracy, ensuring that our parts meet even the most demanding specifications.

In addition, we have developed programmes for producing gears and splines in one set-up, which allows us to produce complex parts with greater efficiency and precision. Our Mazak Integrex machines, which feature up to 72 tool carousels and multi chillers, can hold tolerances as tight as 3 microns, ensuring that our parts are of the highest quality and performance.

We also offer full and complex CAD programming direct from design drawing step-files, which allows us to optimise our processes and ensure that our parts are manufactured to the exact specifications of our customers. With our skilled technicians and rigorous quality control processes, we can deliver parts that meet the highest standards of quality and reliability.

Whether you need a single custom part or a large production run, we have the expertise, equipment, and capabilities to meet your needs.